The Waste Refrigerator Recycling Line by Suny Group is a highly efficient and environmentally friendly solution designed for the recycling of end-of-life refrigerators and cooling appliances. The line features a high level of automation, stable operation, and low labor requirements, making it suitable for large-scale recycling facilities. It complies with environmental standards and maximizes the recovery of valuable materials.

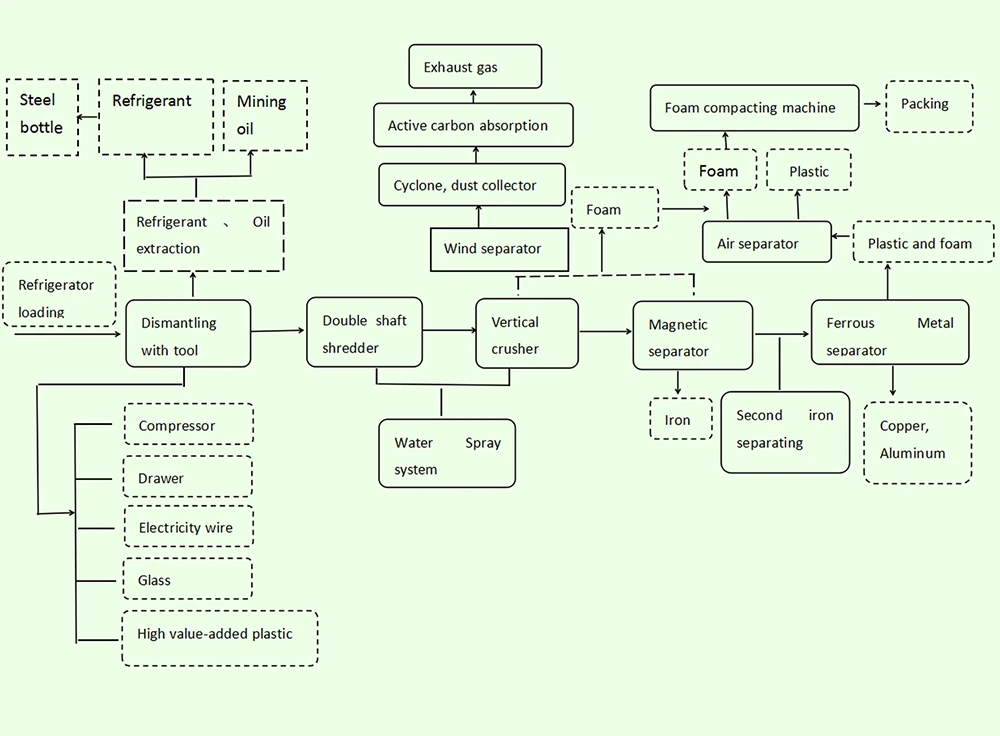

In the working process, waste refrigerators are first fed into the system and undergo safe pretreatment, including degassing and component removal to ensure compliant handling. The units are then shredded into uniform pieces by a heavy-duty shredder. Advanced magnetic separation, eddy current separation, and air separation systems are used to sort different materials accurately. Foam insulation is efficiently separated and collected, while dust and emissions are controlled through a dedicated filtration system.

The final output is a major advantage of this recycling line. Clean steel, copper, and aluminum are discharged separately with high purity, suitable for direct reuse or smelting. Recovered plastics and foam materials are collected efficiently, increasing overall recycling value and profitability.

Workflow

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

Raw Material

Final Products

Main Parameter

| Capacity | 600 units/hour (the production capacity is based on the processing of 120L-220L refrigerators, which can handle refrigerators with specifications above 220L) |

| Equipment size | 51000X13000X6500mm (Customizable) |

| Capacity reduction ratio of polyurethane foam |

1/5-1/8

|

| lron recovery rate (weight%) | ≥99% |

| Recovery rate of copper and aluminum (weight %) | ≥97% |

| Plastic sorting rate (weight %) | 97% (<3% foam in recycled plastic) |