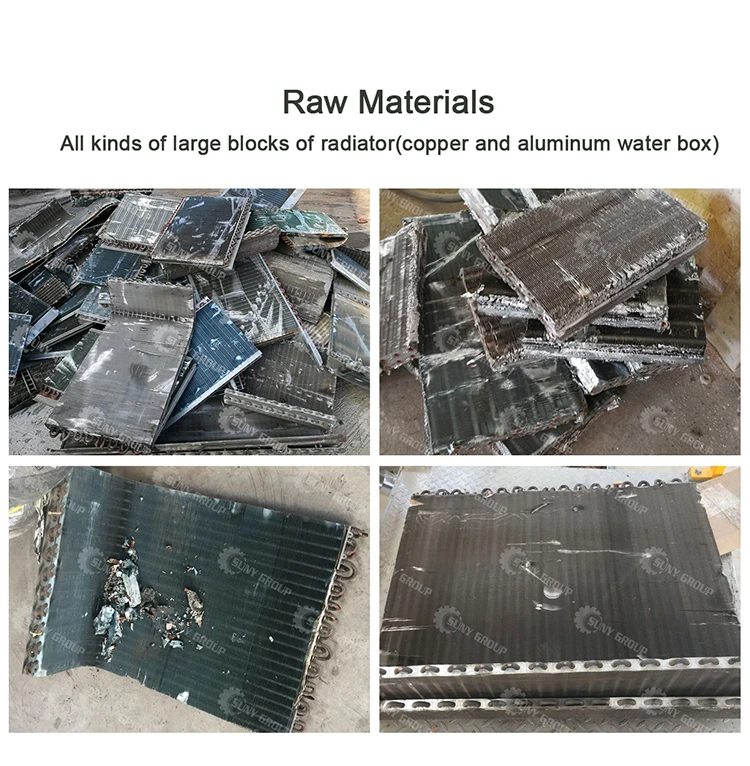

Scrap Radiator Processing Line for Metal Separation is equipped with a complete set of recycling machinery designed for efficient copper and aluminum recovery. The standard configuration includes a radiator cutting machine, fin stripping unit, conveyor system, metal collection bins, and dust control devices. Some advanced lines also integrate automatic feeding and centralized control systems to improve productivity and operational safety.

The processing workflow starts with feeding scrap radiators into the cutting machine, where the frames are trimmed to suitable sizes. The radiators then enter the stripping section, where aluminum fins are mechanically removed from copper tubes through rolling and pulling actions. The separated materials are transferred by conveyors to designated discharge outlets, ensuring continuous and smooth operation.

The final output consists of clean copper tubes and separated aluminum fins with high purity and minimal loss. Copper can be directly sold to smelters or reused in manufacturing, while aluminum is suitable for remelting or further processing. The processing line significantly improves recycling efficiency, metal recovery rates, and overall economic value.

TECHNICAL PARAMETERS

| Model | Capacity(Kg/H) | Sorting Efficiency | Dust removingefficienty | Power(Kw) |

| ZYSRP-1000 | 1000 | 97% | 99% | 55*2 |

| ZYSRP-2000 | 2000 | 97% | 99% | 75*2 |

| ZYSRP-3000 | 3000 | 97% | 99% | 115*2 |

| ZYSRP-5000 | 5000 | 97% | 99% | 145*2 |