Scrap Motor Stator Recycling Plant Line for Copper Recycling is composed of specialized equipment designed for efficient and safe copper recovery from waste motor stators. The standard configuration includes a stator cutting or pulling machine, crusher or shredder, hammer mill, magnetic separator, airflow separator, and dust collection system. Conveyors and centralized control cabinets are also integrated to ensure continuous and stable operation.

The recycling process starts with feeding scrap motor stators into the cutting or pulling unit, where the steel housing is opened and copper windings are loosened. The material then enters the crushing and hammer milling stage to fully liberate copper from iron cores and insulation. Magnetic separation removes steel components, while airflow separation accurately separates copper from light insulation materials.

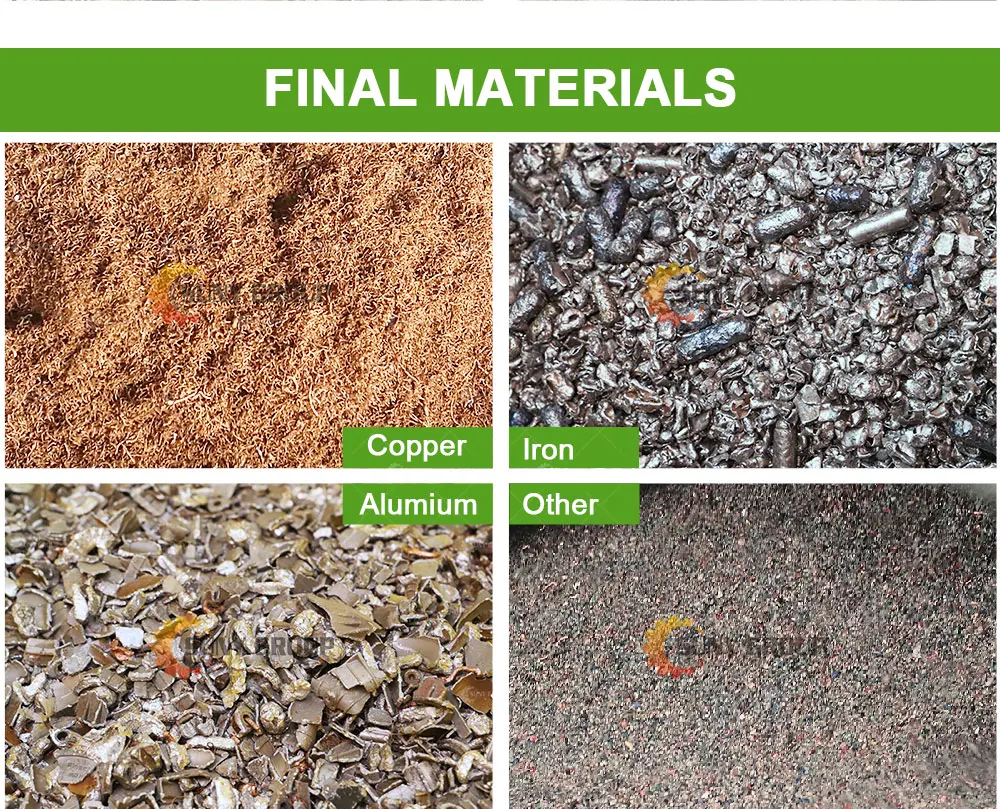

The final output consists of clean copper granules or copper wires with high purity, separated steel, and insulation waste. Recovered copper can be directly reused in smelting and manufacturing industries, while steel is recycled separately, achieving high recovery efficiency and strong economic value.

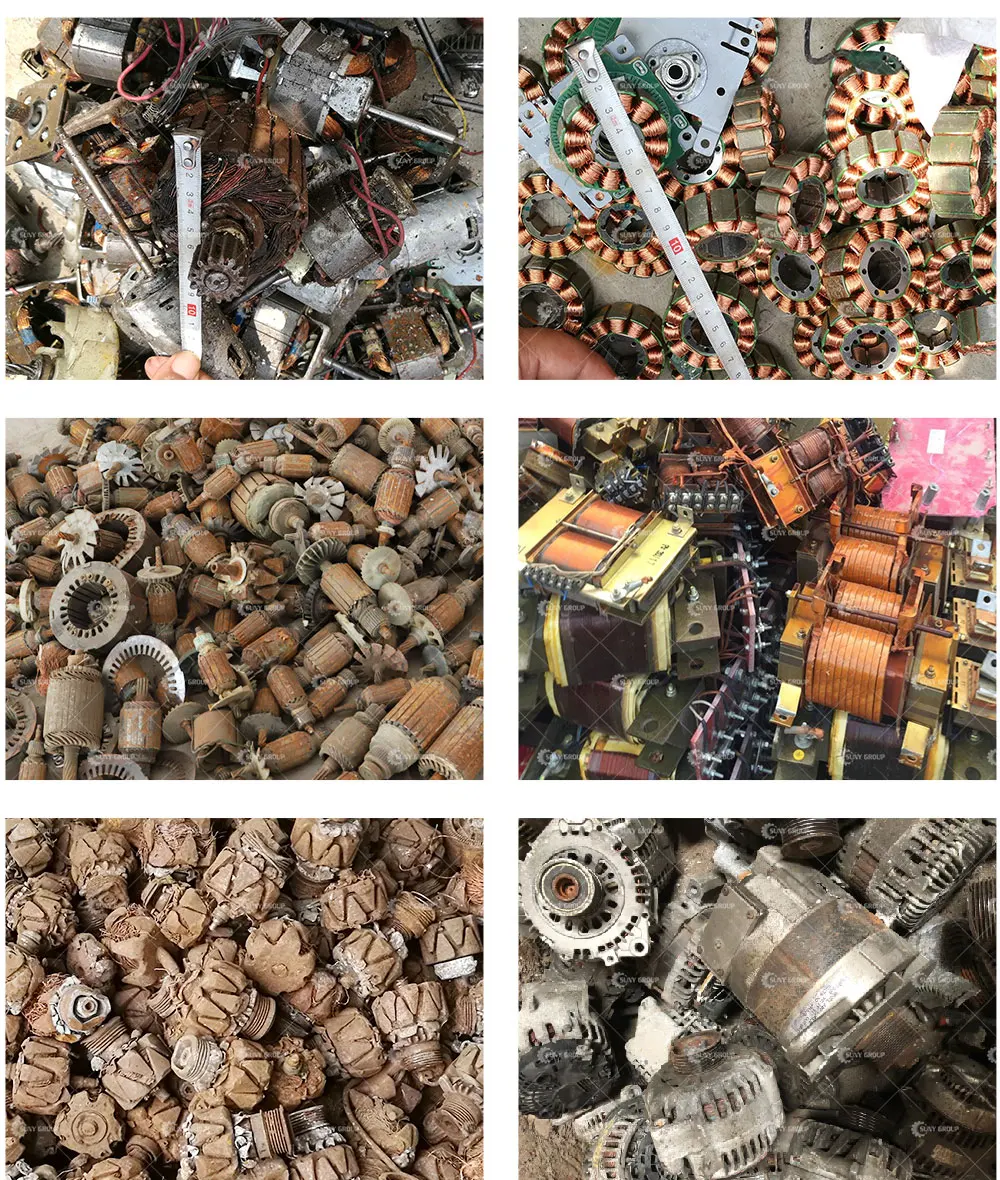

RAW MATERIALS

MAIN PARAMETERS

| Model | Capacity(Kg/t) | Power(Kw) | Size(m) | Weight(T) |

| ZYSMR-1000 | 26.5 | 177 | 25*6*6 | 1 |

| ZYSMR-2000 | 47 | 303 | 40*6*6 | 2 |

| ZYSMR-3000 | 50.5 | 345 | 45*6*6 | 3 |

| ZYSMR-5000 | 67.5 | 493 | 50*10*6 | 5 |