Fully automated lithium battery recycling line is designed to process spent lithium-ion batteries efficiently, safely, and continuously. The system integrates automatic feeding, deep discharging, multi-stage crushing, and precise separation, minimizing manual intervention and ensuring stable operation. With advanced dust collection and negative pressure control, the entire process meets high environmental and safety standards.

The working process begins with automatic feeding and discharging to eliminate residual electrical risks. Batteries are then crushed in a sealed system, followed by screening and magnetic separation to remove steel components. Air separation and gravity separation are applied to separate light materials and aluminum, while fine classification systems accurately isolate copper and black mass. Intelligent control ensures stable particle size and high recovery rates.

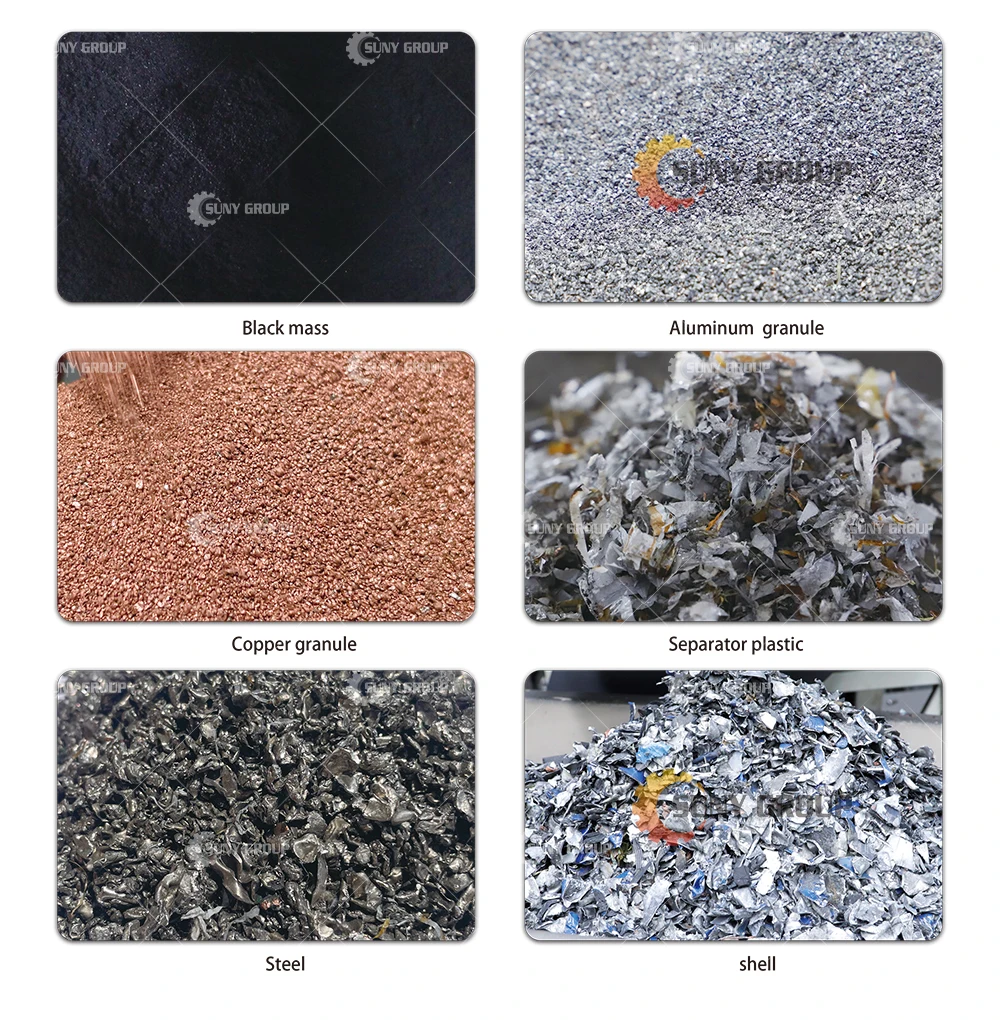

The final outputs include high-purity copper granules, aluminum fractions, steel, and lithium-containing black mass. Copper is a key highlight of this line, featuring low impurity content, uniform size, and excellent conductivity, making it suitable for direct resale or further refining. The automated design significantly improves copper recovery efficiency and overall economic returns.

Product Application

The raw materials for a fully automated lithium battery recycling line include spent lithium-ion batteries from electric vehicles, energy storage systems, consumer electronics, and power tools. Typical inputs include battery cells, modules, and packs with various chemistries such as NCM, NCA, and LFP.

Final products

The final products are black mass, aluminum granule, copper granule, plastic, steel shell and separator plastic etc. The output will vary depending on the type of battery.

Technical Parameters

| Model | Capacity | Raw Material | Final Product |

| LDC-300 | 200-300 Kg/H | Lithium-ion Battery | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |

| LDC-500 |

500 Kg/H

|

Lithium-ion Battery | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |

| LDC-800 | 800 Kg/H | Lithium-ion Battery | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |

| LDC-1000 | 1T/H | Lithium-ion Battery | 1Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |

| LDC-1500 | 1.5T/H | Lithium-ion Battery | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |

| LDC-2000 | 2T/H | Lithium-ion Battery | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite,Powder |