The fully automated copper wire granulation line is an advanced recycling solution designed for high-capacity copper wire processing with minimal labor input. It integrates feeding, crushing, granulating, air separation, and dust collection into one intelligent system. With PLC control and stable operation, the line ensures continuous production, high efficiency, and low operating costs, making it suitable for large-scale copper recycling plants.

In the working process, mixed copper wires are first conveyed into the crusher, where they are cut into uniform particles. The material then enters the granulator for fine processing, ensuring optimal liberation of copper from plastic insulation. After granulation, an efficient air separator and vibration system separate copper granules from plastic with high accuracy. Advanced sorting technology guarantees clean and thorough separation without secondary contamination.

The final output is a key advantage of this fully automated line. The copper granules are bright, uniform, and reach high purity, ready for direct sale, melting, or reuse in copper manufacturing. Plastic granules are clean and dry, suitable for further recycling or secondary processing. The stable, high-quality output significantly increases recycling value and overall profitability.

Raw Material

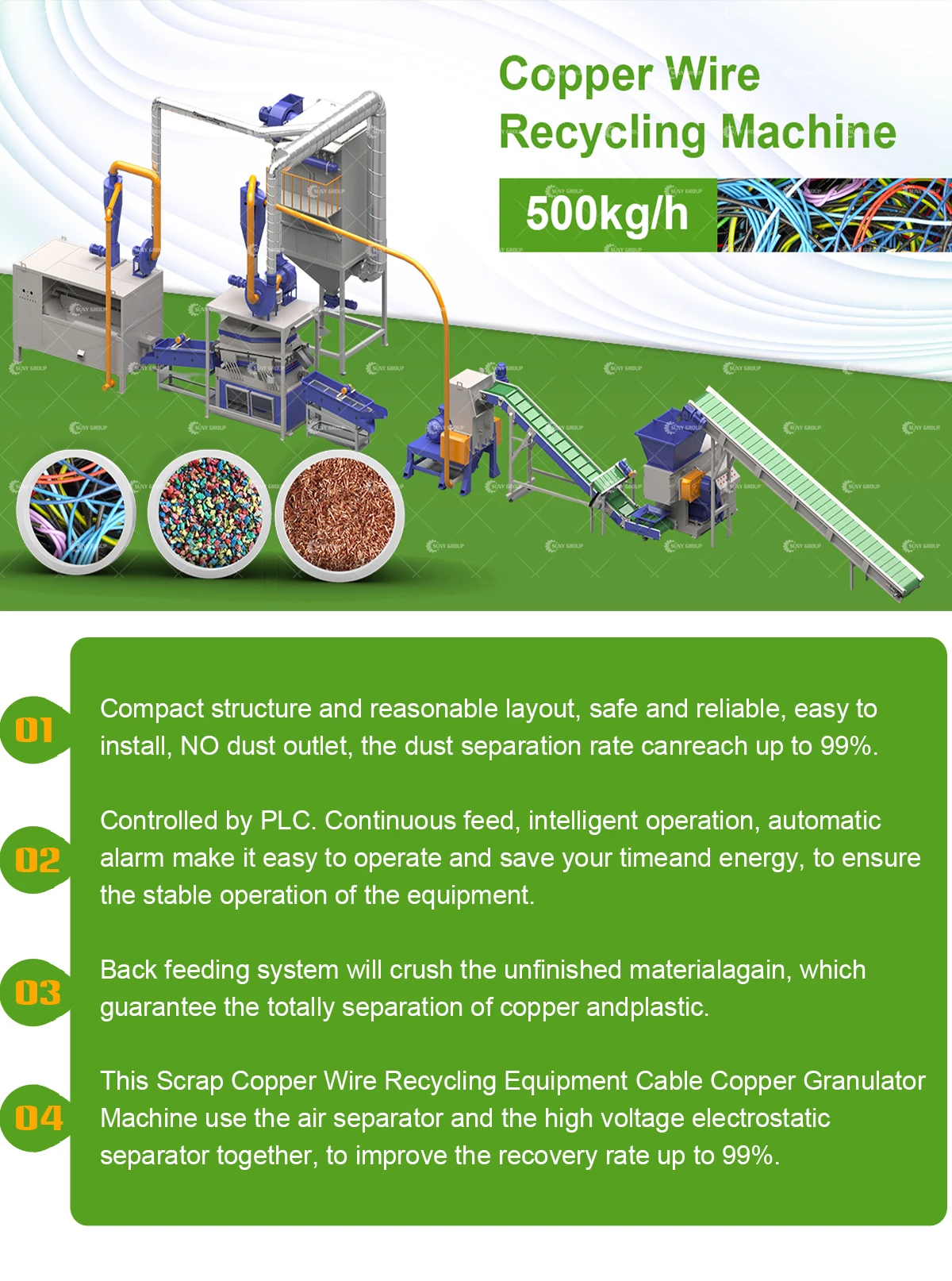

The Copper Wire Recycling Machine is dry type structure, mainly used to all kinds of waste copper wire, the copper wire will be separated into tiny copper rice and PVC. This machine can recycle the copper wire which diameter is 0. 3mm-20mm. Automobile electrical wire or the electric wire of car, motorcycle electric wire, computer case wire and communication cable, etc.

Final Products

Copper Wire Recycling Machine process the waste electric wire and cable into copper and plastic granule. Copper is separated from the plastic, separation efficiency can be 99%. For the copper granule, it can be sold directly or go to further refining. Through our copper electrolysis machine, the copper can be refined into cathode copper in above 99.99% purity. The plastic granules normally are PVC or rubber material, it can also be sold directly.

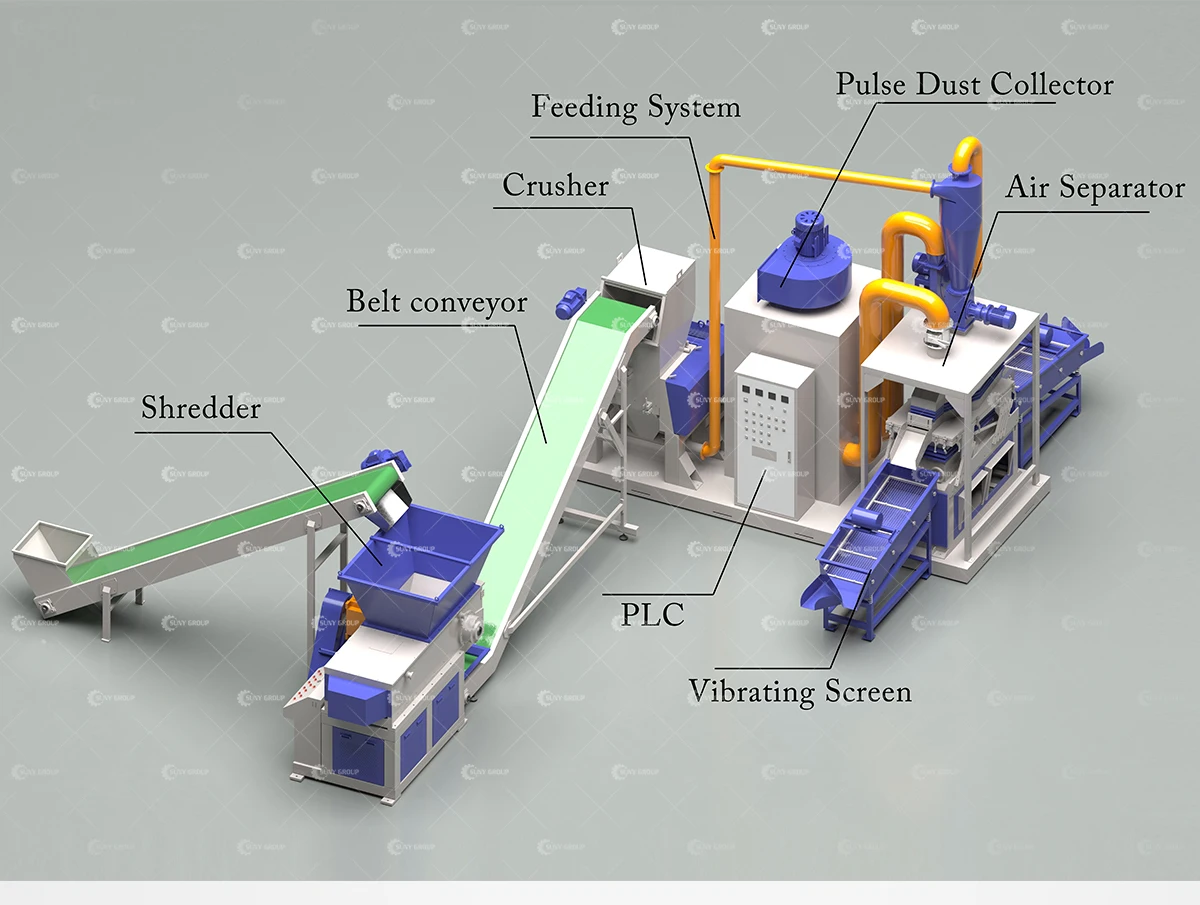

Product Structure

The Copper Wire Recycling Machine is dry type structure, mainly used to all kinds of waste copper wire, the copper wire will be separated into tiny copper rice and PVC. This machine can recycle the copper wire which diameter is 0.3mm-20mm. Automobile electrical wire or the electric wire of car,motorcycle electric wire, computer case wire and communication cable, etc.

Working Process of Copper Wire Recycling Line

1. Put wasted cable into the crusher machine, they will be cut into granules first. during this process, copper and plasticareseparated but still mixed together.

2.Then the granules are sent to air separator for separation, according to the gravity difference and through air blow, the copperand plastics are separated success sully and comes out from different sides.

3. At last we collect the separated pure copper and plastic.

Product Feature