E-Waste Printed Circuit Board (PCB) Recycling Plant is composed of a complete set of mechanical and physical separation equipment designed for efficient material recovery. The main configuration typically includes a double shaft or single shaft shredder for primary size reduction, a hammer mill or crusher for further liberation, followed by magnetic separators, air classifiers, and electrostatic separators. Dust collection and control systems are also integrated to ensure safe and environmentally compliant operation.

The recycling process begins with feeding waste PCBs into the shredder, where boards are broken into smaller pieces. These materials are then finely crushed to fully separate metal from non-metal components. Magnetic separation removes ferrous materials, while air and electrostatic separation accurately divide metals from resin and fiberglass.

The final output includes high-purity copper granules, mixed metal fractions, and non-metal powder. Recovered metals can be reused in smelting and manufacturing industries, while non-metal materials are applied in construction fillers or composite products, achieving efficient and sustainable e-waste recycling.

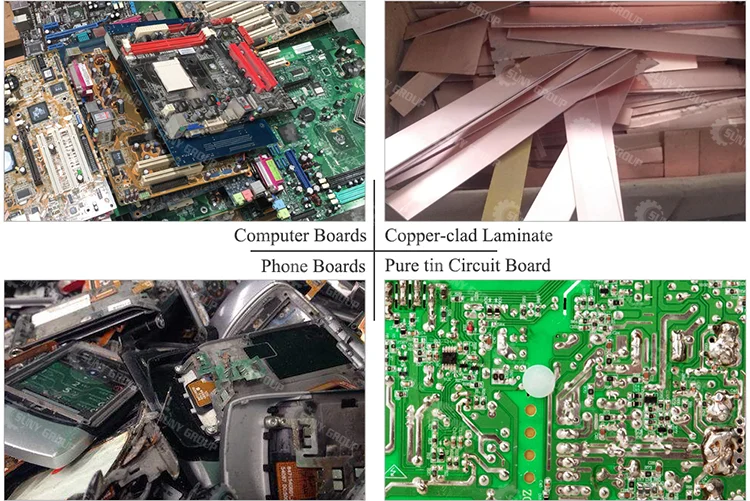

PRODUCT APPLICATION

FINAL PRODUCTS

Because of the high value of the metals, fiber and resin, there is no doubt that this plant not only help to change waste into treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

PRODUCT STRUCTURE

TECHNICAL PARAMETERS

| Model | Capacity | Power | Weight | Dimension (m) |

| ZYPCB-300 | 300 Kg/H | 102 Kw | 15 Ton | 20*5*5 |

| ZYPCB-500 | 500 Kg/H | 134 Kw | 20 Ton | 25*6*5 |

| ZYPCB-1000 | 1000 Kg/H | 194 Kw | 30 Ton | 30*6*5 |