The single-shaft shredder for copper wire is a professional recycling machine designed to process various types of scrap copper cables, wires, and harnesses. The equipment adopts a heavy-duty rotor, high-strength alloy steel knives, and a wear-resistant screen to ensure stable operation, strong cutting force, and uniform output size. An intelligent hydraulic pusher system guarantees continuous and even feeding, improving shredding efficiency while reducing energy consumption.

In the working process, copper wires are fed into the shredding chamber through a conveyor or manually. The rotating shaft drives the knives to cut, tear, and shear the materials against the fixed counter knives. After being shredded to the required size, the material passes through the screen and is discharged automatically. Oversized pieces remain in the chamber for further shredding until they meet the output standard.

The final output consists of evenly sized copper wire fragments mixed with insulation. These shredded materials are ideal for downstream processing such as granulation, air separation, and electrostatic separation. The system improves copper recovery rate, reduces transportation volume, and provides reliable, clean feedstock for efficient copper recycling lines.

WORKING PRINCIPLE

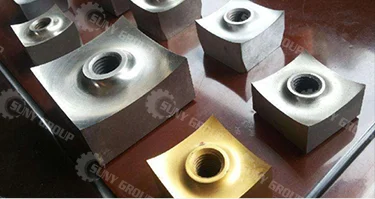

Waste Cable Single Shaft Shredder Machine for Recycle consists of a knife disc and a static knife to complete shredding material. Cutter is composed of a base shaft and several shape quadrilateral knife block.

MACHINE FEATURES

Waste Cable Single Shaft Shredder Machine for Recycle is suitable to recycle a variety of bulk solid materials, refractory materials, plastic containers and plastic barrels, plastic films, fibers, paper. Shredded particles can be small to 20mm according to different needs.

Single shaft shredder consists of a knife disc and a static knife to complete shredding material.

Blade quality have 9CrSi, Cr12MoV, SKD- II, D2 etc. Can be customized according to customer.

Special screen can be designed according to the type of your raw materials.

Hydraulic-driven pusher adopts advanced sealing design, can remove the dust in shredding process.

TECHNICAL PARAMETERS

| Model | Motor Power (kw) | Rotor-knives (pcs) | Blade Material | Rotor Diameter (mm) | Rotor Speed (r/min) | Cutting Chamber (mm) | Hydraulic Power (kw) | Cylinder Stroke (mm) | Machine Size (mm) | Weight (kg) |

| ZY-S600 | 22 | 26+4 |

Cr12MoV

SKDII

D2

|

260 | 75 | 600×600 | 2.2 | 600 | 1800x1600x1850 | 2200 |

| ZY-S800 | 45 | 36+6 |

Cr12MoV

SKDII

D2

|

400 | 75 | 800×800 | 3 | 800 | 2200x1780x2100 | 3700 |

| ZY-S1000 | 55 | 48+6 |

Cr12MoV

SKDII

D2

|

400 | 75 | 1000×1000 | 4 | 1000 | 2500x1850x2300 | 4500 |

| ZY-S1200 | 75 | 58 |

Cr12MoV

SKDII

D2

|

500 | 80 | 1200×1200 | 5.5 | 1200 | 3500x2000x2400 | 7000 |

| ZY-S1500 | 110 | 98 |

Cr12MoV

SKDII

D2

|

550 | 80 | 1500×1500 | 7.5 | 1500 | 4800x2300x2400 | 9800 |