Scrap Copper Baler is a heavy-duty recycling machine designed to compress loose scrap copper into compact and uniform bales for efficient handling. The equipment features a robust steel frame, a high-pressure hydraulic system, a feeding chamber, and an automatic bale discharge unit. Its durable structure ensures stable operation and long service life, making it suitable for continuous industrial use in metal recycling facilities.

The working process begins by feeding loose scrap copper into the baler chamber. Once the chamber is filled, the hydraulic system activates and applies strong pressure to compress the material. Through multi-directional compression, the scrap copper is tightly packed into dense bales. After reaching the preset pressure and size, the machine automatically opens the discharge door and ejects the finished bale. The entire process is controlled by an intelligent system to ensure safety and efficiency.

The final output consists of high-density copper bales with uniform size and stable shape. These bales are easy to stack, transport, and store, significantly reducing logistics costs. Compressed scrap copper can be directly supplied to smelters or further processing lines, improving melting efficiency and recycling value.

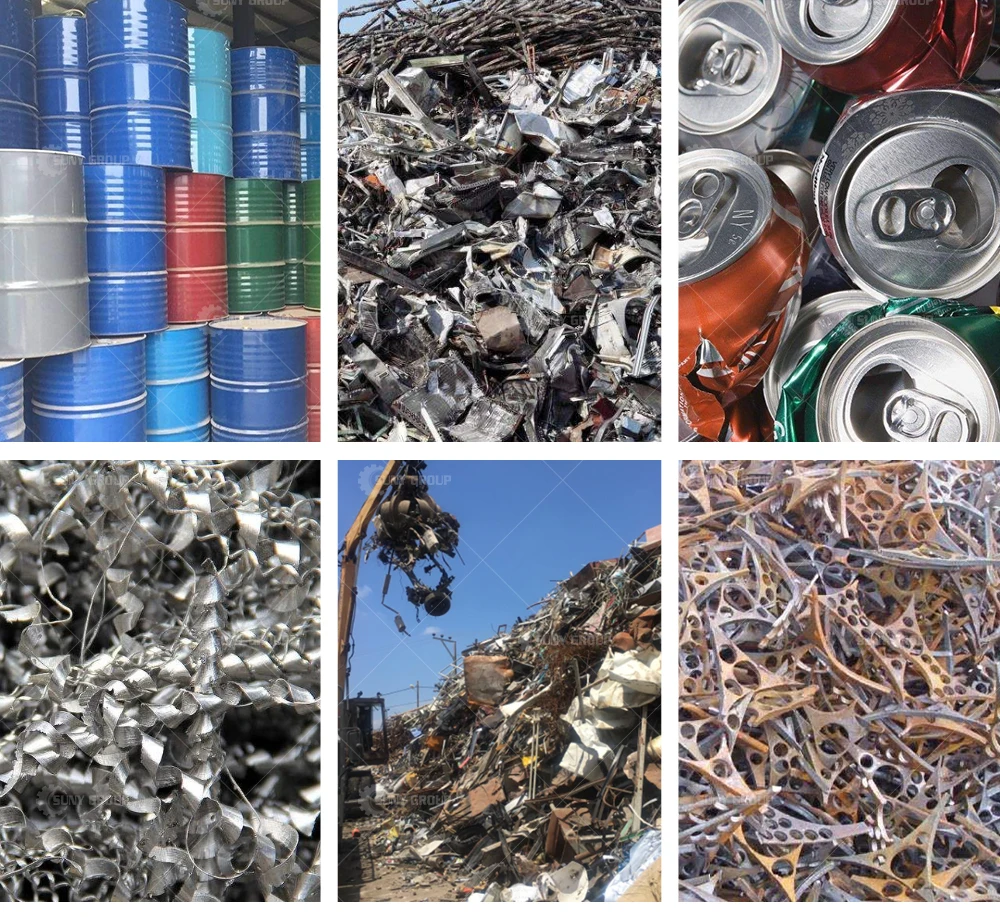

APPLICATION

AFTER PACKING

FEATURE

MODEL AND PARAMETERS

| Model | Capacity (kg/h) | Rotor-knives (pcs) | Counter-knives (pcs) | Blade material | Rotor diameter (mm) | Rotor speed (r/min) | Cutting chamber (mm) | Hydraulic power (kw) | Cylinder stroke (mm) | Machine size (mm) | Weight (kg) |

| ZY- 5600 | 600 | 26+4 | 4 | Cr12MoV/SKDII | 240 | 45-90 | 600×600 | 2.2 | 600 | 1780x1400x1800 | 2800 |

| ZY-S800 | 800 | 46+6 | 4 | Cr12MoV/SKDII | 400 | 45-90 | 810×800 | 3 | 800 | 2400x1680x2000 | 4000 |

| ZY-S1000 | 1000 | 49+4 | 4 | Cr12MoV/SKDII | 400 | 45-90 | 1000×1000 | 4 | 1000 | 3000x2000x2200 | 5500 |

| ZY-S1200 | 1200 | 64+4 | 4 | Cr12MoV/SKDII | 500 | 55-75 | 1200×1100 | 5.5 | 1000 | 3500x2300x2200 | 7000 |