The Motor Stator Copper Removing Machine is an advanced recycling solution developed for efficiently separating copper windings from scrap motor stators. The machine features a strong steel frame, high-precision cutting tools, and an intelligent control system, ensuring stable operation, high efficiency, and long service life. It is suitable for processing various types and sizes of motor stators and is widely used in motor recycling plants, metal recovery centers, and industrial scrap processing facilities.

During the working process, scrap motor stators are fed into the machine manually or via a conveyor. The cutting system accurately opens the stator slots and loosens the copper windings without excessive breakage. The copper is then pulled out smoothly by a stripping mechanism, while the iron stator core remains intact. The entire process is safe, low-noise, and energy-efficient.

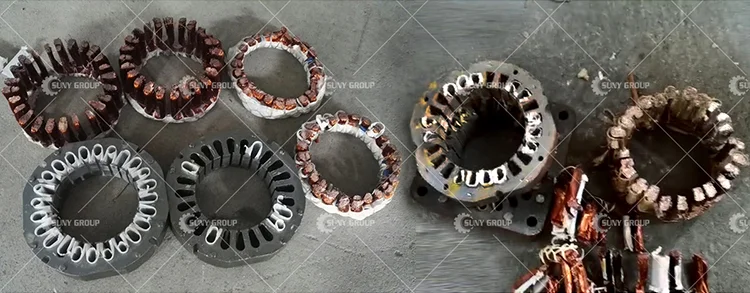

The final output includes clean, high-purity copper windings with minimal insulation, ready for smelting or resale, along with separated iron stator cores suitable for further recycling. This machine significantly improves recovery efficiency and economic value.

Used Motor Scrap Cutting Machine is a kind of waste motor/ waste motor and stator and heavery duty, it can help you to process more easily and efficient. The machine has 3 main parts, one is cutting part for all motor stator , second is grab copper part from small motor stator , last one is extract copper from big motor stator . It’s very cost-effective and convenient in using..

RAW MATERIAL

Motor stator processing range: 50-500mm.

Raw material: Motor stators of household appliances, such as refrigerator, cold drink machine, air conditioner, air fan, air dehumidifier etc, washing machine, electric iron, dust collector, electric cooker, microwave oven, electric oven, electric hair drier, television, radio.

BEFORE RECYCLING

Process range: Stator size more than 5cm, diameter less than 50cm.

AFTER RECYCLING

TECHNICAL PARAMETERS

| Model | Power | Weight | Overall Dimensions |

| ZY-MC500 | 4kw | 480 Kg | 2.6*1.1*1.2 m |