Copper Wire Recycling Machine is an advanced recycling solution designed to efficiently separate copper from plastic or rubber insulation in scrap electrical wires and cables. It is widely used in metal recycling plants, e-waste processing facilities, and cable recycling workshops. By converting mixed copper wires into clean copper granules and plastic output, the machine improves material purity, reduces labor intensity, and increases overall recycling efficiency. Copper wire recycling machines can process various wire types, including household electrical wires, industrial cables, automotive wiring harnesses, and communication cables. With features such as compact design, stable operation, low noise, and minimal maintenance, this equipment plays a vital role in modern copper recycling industries.

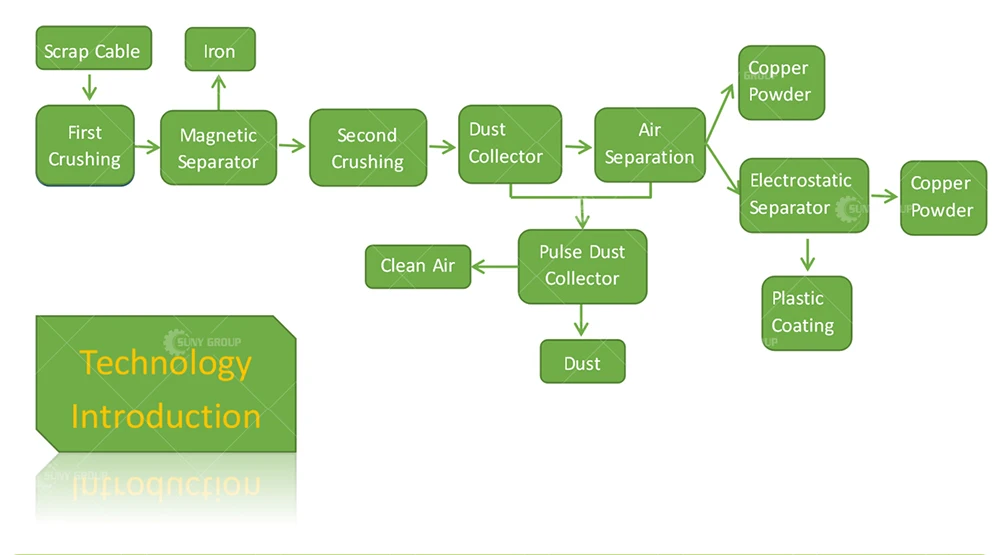

The working process begins with feeding scrap copper wires into the crusher or granulator, where the materials are cut into small, uniform pieces. These granules then pass through an air separation or gravity separation system that effectively separates copper from insulation. A dust collection unit ensures a clean working environment. The final output consists of high-purity copper granules ready for reuse and clean plastic suitable for further processing.

Product Application

The Copper Wire Recycling Machine is dry type structure, mainly used to all kinds of waste copper wire, the copper wire will be separated into tiny copper rice and PVC. This machine can recycle the copper wire which diameter is 0. 3mm-20mm. Automobile electrical wire or the electric wire of car, motorcycle electric wire, computer case wire and communication cable, etc.

Final products

Product Parameters

| Model | Capacity | Weight | Size (m) | Power |

| ZY-TMJ100 | 100-200kg/h | 1850kg | 2.2x2x2.3 | 28kw |

| ZY-TMJ300 |

200 300kg/h

|

2500kg | 3.2×2.1×2.3 | 39kw |

| ZY-TMJ500 | 400-500kg/h | 3850kg | 6.2x5x3.3 | 68kw |

| ZY-TMJ800 | 700-800kg/h | 5500kg | 10.4×2.1×3.3 | 75kw |

| ZY-TMJ1000 | 800-1000kg/h | 8200kg | 12×4.1×4.5 | 95kw |

Process Description

For the small capacity, the cable wires raw materials can be put into the al-in-one machine directly, after crushing, it will using the Air separation system to make the copper and plastic suspended on the screen. Then it can separate the Copper from the plastic by weighting method and the friction force which produced by the Surface of the mesh.