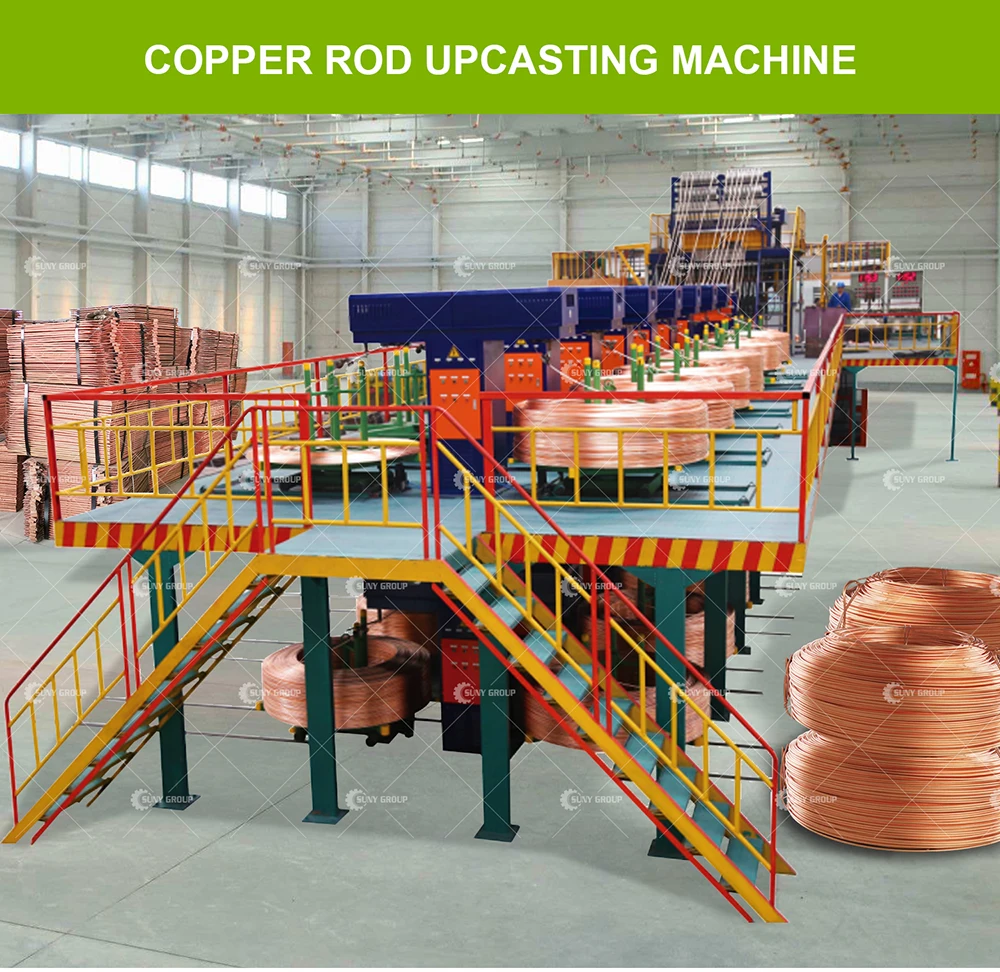

Copper upward continuous casting machine is designed to produce high-quality copper rods and billets from refined copper with excellent structural density and purity. It is widely used in wire and cable manufacturing, electrical industries, and non-ferrous metal processing plants. The upward casting principle effectively reduces oxidation and surface defects, ensuring superior copper quality and stable production.

The working process begins with melting high-purity copper cathodes or copper scrap in a holding furnace. The molten copper is kept at a constant temperature and smoothly fed upward into a water-cooled crystallizer. As the copper rises, it gradually solidifies under controlled cooling conditions, forming a continuous copper rod or billet. The solidified copper is then withdrawn at a stable speed, straightened, and cut to required lengths automatically.

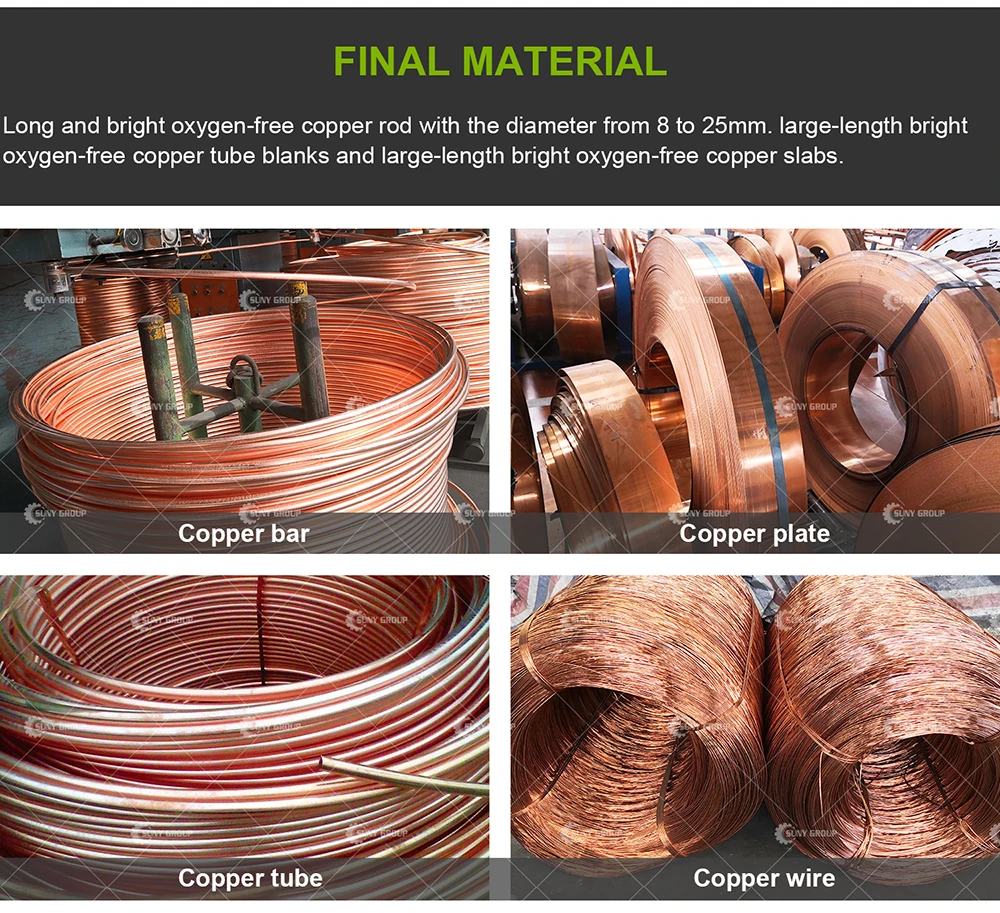

The final output copper is dense, uniform, and free from internal porosity. It features smooth surfaces, consistent diameter, and high electrical conductivity. This premium copper product is ideal for further wire drawing, extrusion, and electrical component production, significantly enhancing material performance and overall manufacturing efficiency.

PRODUCT APPLICATION

Upward continuous casting machinery ( up cast line )

Upward Copper Rod Continuous Casting Full Plant is used to produce the long and bright oxygen-free copper rod with the diameter,from 8 to 25mm. Large-length bright oxygen-free copper tube blanks and large-length bright oxygen-free copper slabs.As a conductive material with high conductivity and low oxygen content, the oxygen-free copper rod is widely used in wire,cable,electromagnetic wire and other industries.

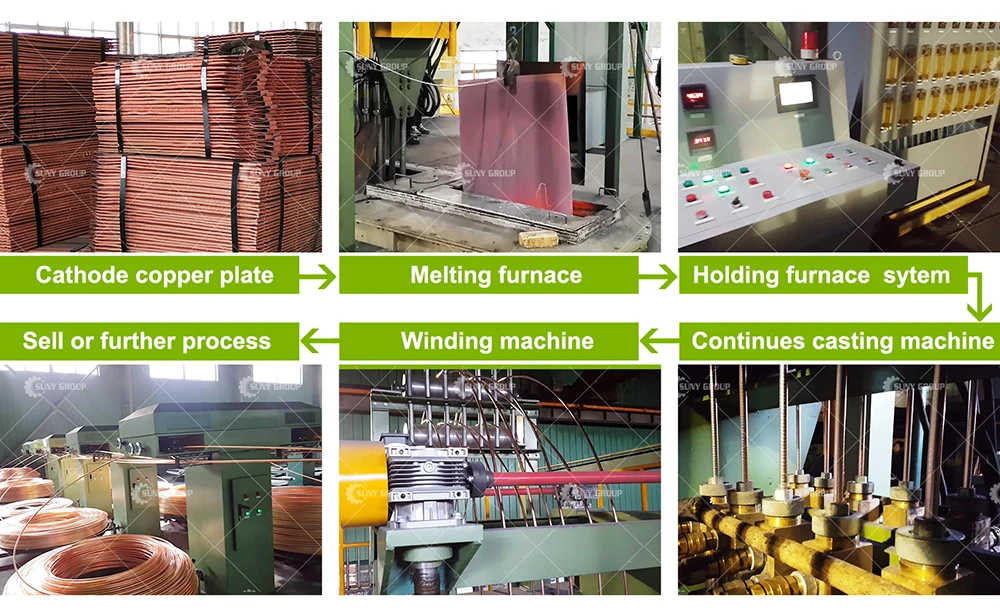

PROCESS DETAILS

Step 1. Cathode copper is directly added to the melting furnace and melted into a liquid by power frequency induction;

Step 2. After melting, the copper liquid will automatically and smoothly overflow into the intermediate holding furnace through the

transition chamber;

Step 3. The copper liquid has a stable reduction process by the covered surface of charcoal;

Step 4. After the reduction, the copper liquid is rapidly crystallized into a cast rod through a crystallizer through the continuous

casting machine in the holding furnace;

Step 5. Every casting rod is equipped with a controller and a torsion bar machine.The casting rod is led from the continuous casting

machine to the controller and the torsion bar through the regulating wheel device to form a circle. After the completion of the

circle, the casting rod is cut and hoisted away for the next process.

TECHNICAL PARAMETERS

| Capacity | 3000 – 12000T/Year |

| Furnace Number | 2 Melting Furnace+1 Heat Preservation Furnace |

| Casting Rod Number |

24 Pcs

|

| Casting Rob Diameter | φ8mm ~ φ20mm |

| Upward Speed | 6.0 ~ 2800mm/min |

| Upward Circular Pitch | 3-6mm ( Adjustable ) |

| Traction Frequency | 0 ~ 800 times/time |

| Traction Way | Servo Motor Tranction |

| Winding Specification | φ1000xφ1550×800 ( mm ) |

| Voltage | 380V, 50Hz, 3Phase |

| Melting Copper Speed | 1550 Kg/H |

| Maximum Operating Power | ≤560 Kw |

| Power Consumption | ≤330 Kwh/T |